Acetylene

gas is highly explosive gas provided it is liquefied, compressed, heated, or

mixed with air. The gas is a colorless, combustible gas with a distinctive

odor. Being a combustible gas, it needs special precautions during its

production and handling. Apart from polyurethane and polyester plastic

industry, it is also employed for welding, cutting and related processes. Now

you must be pondering, who will use it? For your kind information, acetylene

gas is only employed by trained professionals by using suitably designed

handling equipment.

Professionals working with the need to keep in mind a number

of points in order to maintain safety and security. Some of the points include:

· Avoid storing

or injecting acetylene gas into any type of bottle, vessel, tank, or enclosure.

·

Inappropriately

stored acetylene gas is unstable.

·

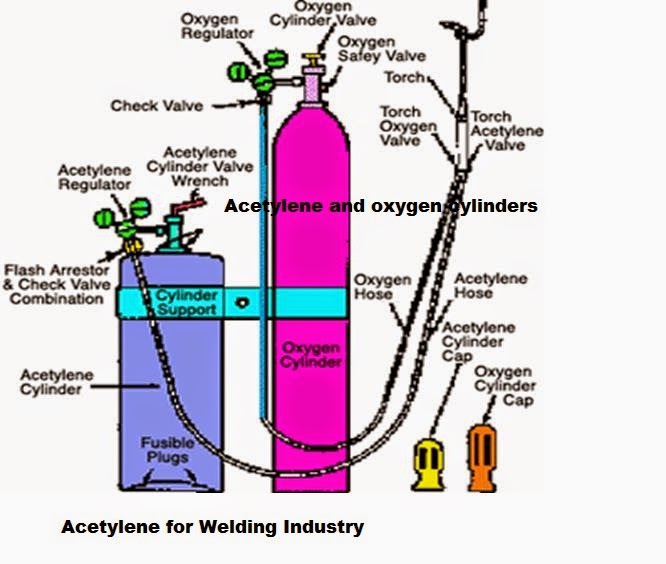

Check

the regulators carefully

·

Get

the FLAME ARRESTORS AND CHECK VALVES checked by professionals

·

The

cylinders should be properly checked

·

Movement

of cylinders should be done with proper care.

·

The

Cylinders should be kept away from flame or heat.

Do

you belong to an industry which needs acetylene on a frequent basis? If your

answer is yes, then you have to look for the acetylene gas plants manufacturers

and suppliers. Once you start making online search, you will find India a

reliable country as it has a number of well established companies. The Indian acetylene gas plant manufacturers and suppliers have a number of customers worldwide due

to latest technology, low price and excellent customer services.